Functionalizing polymers!

Vision and mission

Nexam Chemical’s vision is to be a recognized world leader in the field of property modification of polymer materials through heat-activated crosslinking.

The Nexam Chemical’s mission is to contribute to a more resource-efficient and sustainable society by using advanced crosslinking chemistry to reduce the limitations of polymer materials.

Business

Nexam Chemical develops technology and products that make it possible to significantly improve the production process and properties of most types of polymers in a cost-effective manner and with retained production technology.

Nexam Chemical’s technology make the polymers more temperature and chemical resistant, stronger, tougher and more sustainable. The improvements in properties, by using Nexam Chemical’s technology, make it possible to replace metals and other heavier or more expensive materials with polymers in a number of applications. In applications where polymers are already used, Nexam Chemical’s products can improve the manufacturing process and reduce the amount of material used. This enables for more environmental friendly alternatives. Our technology also enables recycled polymers to regain its original performance by “repairing” the polymer.

Read more

Nexam Chemical’s technology and products can improve the properties of plastics and processability in several steps of the value chain.

Customer offer

Nexam Chemical offers, through masterbatch, user-friendly products that, cost-efficiently and without additional investments, enhance the properties of polymeric materials using conventional processing equipment. With masterbatch, the customer can easily add a pre-mixed high dose product in the production process when manufacturing it’s on end-product.

Market and market strategy

The plastics market is a mature industry characterized by stable growth and a continuous demand for cost-effective innovations. The market drivers are:

- Innovation need – replacement of existing materials, e.g. metal, with lighter materials

- Process och material efficiency – lower cost

- Continuous growing use of plastics

- Increasing sustainability requirements– recycling, life cycle

- Increased regulations for health and safety – REACh

The global plastics production amounts yearly to approximately 320 million tons and Nexam Chemical’s products has a potential to add value to a large part of this market. To be able to address this large market, Nexam Chemical has chosen a strategy that, at each time, focuses on three well-defined areas where the company’s technology and products work very well.

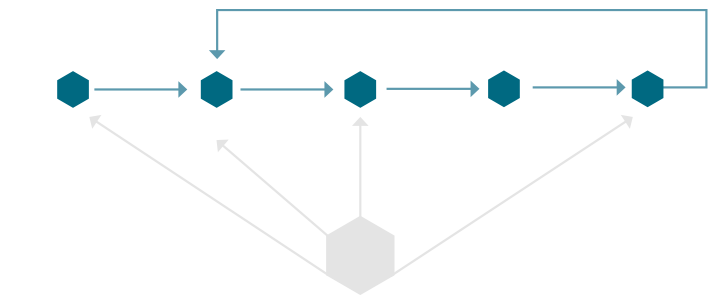

To be added as a new focus area, Nexam Chemical’s products need to have a strong “proof-of-concept”. After that, business with a first commercial customer, leading within its industry, needs to be established. In the next step, the goal is to reach five commercial customers within the area, and then initiate the commercialization of a new focus area.

Nexam Chemical’s three current focus areas are:

- Polyethylene pipe

- Polyester foam

- High performance plastics

Patented technology

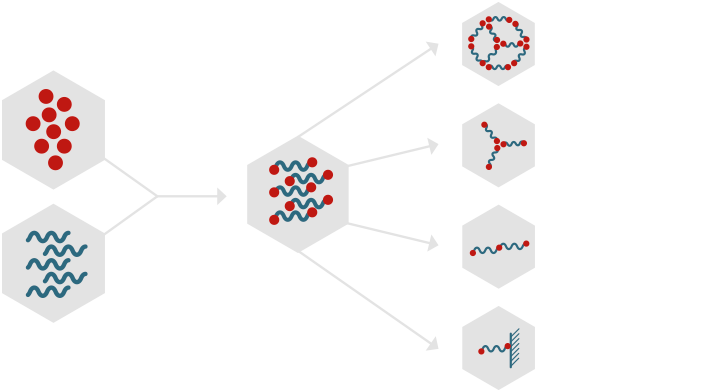

Nexam Chemical’s business is based on a self-developed and patented technology called “connecting molecules”. Nexam Chemical develop reactive chemistry and our molecules and products enhance the properties and performance in a number of different polymeric materials. Our technology connects polymer chains in different ways through heat activation during the production process.

Polymers are made up of small coal-based building blocks that are linked together to a long chain. From these long chains, there are small ends that our molecules can cling on to. Nexam Chemical´s molecules act as a handle that can connect to two identical polymer chains or a polymer chain with a completely different material, such as carbon fiber.

Nexam Chemical’s products can connect molecules in four different ways:

- Crosslinking. Among other things used for production of plastics that are exposed to high temperatures and at the same time still need to retain shape and properties. One example is pipes for transportation of hot water.

- Chain Branching. It is for example used when manufacturing large infrastructural pipes in polyethylene (1-2 m in diameter) where our product allows the pipe to maintain its shape until it is solidified.

- Chain extension. For example used for recycling polyester (plastic chains that have been broken can be re-connected), properties are recovered and value created.

- Compatibilization. Can be used to improve the mechanical properties of plastic when it is mixed with high levels of fillers, e.g. glass fiber or flame retardants.

These four connecting techniques make it possible to create different properties and can be used separately or together. Common for the different methods is that they improve material properties and in many cases lead to reduced manufacturing cost for our customers.

Patent strategy

Nexam Chemical has a patent strategy that pro-actively applies for patents that protect its technology, product and process development.